Micron And Nanya Partner For 42nm DRAM Process Technology

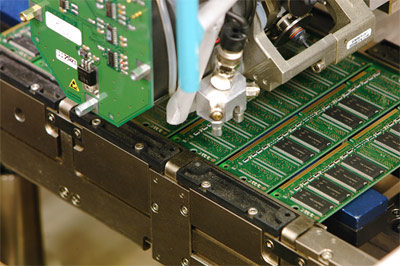

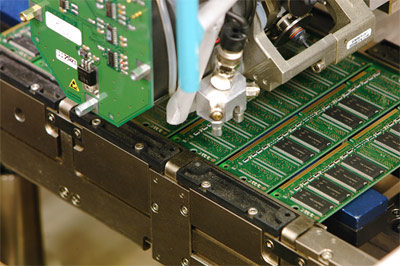

Before long, you'll need a microscope to see the DIMM you're trying to install in your new gaming rig. Sure, we're exaggerating somewhat, but process technologies continue to shrink at a record rate. Micron has been making news lately with their advancements in NAND technology, and now the company has partnered with Nanya in order to unveil a new 42-nanometer DRAM process technology, with a 3X-nanometer process working in the lab.

As you would expect, the new 42-nanometer process uses the more efficient and reliable copper metallization technology, and this device can produce a 2Gb memory module that provides lower power, higher-performance, greater density and smaller die sizes.

In plain terms, this advancement makes it easier for DIMM modules to hold more memory while draining less power, which could mean that even bigger RAM modules will be on the market soon (while prices of existing ones fall). Not sure about you, but we'll take all the RAM we can take. Windows 7 seems to love that stuff.

As you would expect, the new 42-nanometer process uses the more efficient and reliable copper metallization technology, and this device can produce a 2Gb memory module that provides lower power, higher-performance, greater density and smaller die sizes.

In plain terms, this advancement makes it easier for DIMM modules to hold more memory while draining less power, which could mean that even bigger RAM modules will be on the market soon (while prices of existing ones fall). Not sure about you, but we'll take all the RAM we can take. Windows 7 seems to love that stuff.

MICRON, NANYA UNVEIL 42-NANOMETER DRAM PROCESS TECHNOLOGY – REDUCES MEMORY POWER CONSUMPTION, INCREASES PERFORMANCE

Companies Continue DRAM Advancement with 3X-nanometer Process Technology Working in the Lab

Announcement Highlights

· Micron and Nanya today unveiled a new 42-nanometer DRAM process technology, with a 3X-nanometer process working in the lab

· Staying on the leading-edge of scaling, the new 42-nanometer process uses the more efficient and reliable copper metallization technology

· The 42-nanometer process produces a 2Gb memory device, providing lower power, higher-performance, greater density and smaller die sizes

BOISE, Idaho, and TAOYUAN, Taiwan, February 8, 2010 – Micron Technology, Inc. and Nanya Technology Corporation today announced that they have jointly developed a 2-gigabit (Gb) DDR3 memory device using their new copper-based 42-nanometer (nm) DRAM process technology. DDR3 is the predominant memory technology used in high-performance computing applications including servers, notebooks and desktop computers.

The move to smaller process geometries is fundamentally important for maintaining manufacturing cost efficiencies while also providing benefits for customers including lower power, higher performance, greater density, and smaller die sizes. The new 42nm process now makes 1.35-volts the standard, mainstream voltage requirement, compared to 1.5-volt with previous generations. Reducing memory power consumption is critical to today’s server environments, where power and cooling infrastructure costs can be comparable to the costs for the server equipment. With increasing memory requirements in servers, it has been estimated that memory power consumption can be up to 21-watts per module.* The 1.35 voltage can provide a savings of up to 30-percent in these applications, reducing both power and cooling requirements.

Faster memory speed grades are important for achieving maximum system performance. By shrinking process technology, the new 2Gb 42nm DDR3 device delivers improved memory performance capable of reaching up to 1866 megabits per second. In addition, the small die size coupled with the 2Gb density of the 42nm DDR3 device enables modules up to 16GBs.

“With the move to 42nm – and with a 3Xnm process working in our R&D fab in Boise – Micron’s expertise in copper metallization and proprietary cell capacitor technology has enabled us to stay on the cutting-edge of DRAM process design and innovation,” said Robert Feurle, vice president of DRAM marketing. “The addition of this new 2Gb 42nm device to our DRAM product line strengthens our already rich portfolio of memory solutions for customers’ end applications.”

“We are very pleased to offer this 2Gb DDR3, the most competitive DRAM device in production, to our customers,” said Dr. Pei Lin Pai, vice president of global sales and marketing and spokesman for Nanya. “Nanya plans to serve the server and PC market, as well as the consumer market, with this latest technology device.”

Copper: The Path to Higher Quality and Reliability

The new 42nm DRAM process technology uses the more efficient and reliable copper metallization technology, allowing Micron and Nanya to stay on the leading-edge of process scaling. Micron has long recognized the benefits of copper in aiding DRAM scale, and has continued to leverage and refine the technology for nearly a decade. When compared to other metallization techniques, such as aluminum, copper is recognized as the more extendible, reliable and cost-effective approach for advancing process geometries and enhancing product performance. As Micron and Nanya continue to scale, moving to their next-generation 3Xnm process technology, the companies are building on their strong copper foundation to deliver high-quality and highly reliable products.

Availability

Sampling is scheduled to start in the second calendar quarter of 2010 with production ramp planned for the second half of the year.

*Dr. Dobb’s, March 5, 2009, The Problem of Power Consumption in Servers - http://www.drdobbs.com/215800830?pgno=1 <http://www.drdobbs.com/215800830?pgno=1>